API 5L Gr. B/X42 /X52 /X60 /X65 Psl2 Kabhoni Simbi Mutsetse Pipe

| Magiredhi | API 5L Giredhi B, X42, X52, X56, X60, X65, X70, X80 |

| Nhamba Yekutsanangurwa | PSL1, PSL2 |

| Dhayamita Yekunze | 1/2” kusvika 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches kusvika 40 inches. |

| Purogiramu yeKukora | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, kusvika SCH 160 |

| Mhando dzeKugadzira | Yakasungirirwa isina musono (Yakaputirwa nemoto uye yakaputirwa nechando), Yakasungirirwa ERW (Yakaputirwa nemagetsi), SAW (Yakaputirwa neArc Welded) muLSAW, DSAW, SSAW, HSAW |

| Rudzi rwemagumo | Migumo yakachekwa, Migumo isina kujeka |

| Hurefu hwehurefu | SRL (Kureba Kwega Kusina Kurongeka), DRL (Kureba Kwakaviri Kusina Kurongeka), 20 FT (mamita matanhatu), 40 FT (mamita gumi nemaviri) kana, yakagadzirirwa |

| Zvivharo zvekudzivirira | purasitiki kana simbi |

| Kurapa Kwepamusoro | Pendi yeChisikigo, Yakapendwa neVarnish, Dema, FBE, 3PE (3LPE), 3PP, CWC (Huremu hweConcrete Yakaputirwa) CRA Yakaputirwa kana Yakaiswa Mutsetse |

Pipe yeAPI 5L inoreva pombi yesimbi yekabhoni inoshandiswa mumasisitimu ekutumira mafuta negasi. Inoshandiswawo kutakura zvimwe zvinwiwa zvakaita seutsi, mvura, nematope.

Tsanangudzo yeAPI 5L inosanganisira mhando dzekugadzira dzakasungirirwa pamwe chete uye dzisina musono.

Mhando dzeWelded: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Mhando dzakajairika dze API 5L welded pombi ndeidzi:

ERW: Kuwedera kwemagetsi kunoshandiswa papombi dzine dhayamita iri pasi pe 24 inches.

DSAW/ SAW: Kubatanidza arc inonyudzwa nemativi maviri/kusanganisa arc inonyudzwa nepasi ndeimwe nzira yekusanganisa inogona kushandiswa panzvimbo peERW yepombi ine dhayamita hombe.

LSAW: Kuwedera kweArc kwakanyudzwa mumvura kwenguva refu kunoshandiswa papombi ine dhayamita inosvika masendimita makumi mana nemasere. Inozivikanwa senzira yekugadzira JCOE.

SSAW/HSAW: Kubatanidza arc inonyungudika/kubatanidza arc inonyungudika inosvika dhayamita ye 100 inches.

Mhando dzeMapaipi Asina Musono: Mapaipi Asina Musono Anopisa uye Mapaipi Asina Musono Anopisa

Pombi isina musono inowanzo shandiswa pamapombi madiki ane dhayamita shoma (kazhinji asingasviki masendimita makumi maviri nemana).

(Mapaipi esimbi asina musono anonyanya kushandiswa kupfuura mapaipi akasungirirwa padhayamita yemapaipi ari pasi pe150 mm (6 inches).

Tinopawo mapaipi akafara asina musono ane dhayamita hombe. Tichishandisa nzira yekugadzira inopfurwa nemoto, tinogona kugadzira mapaipi asina musono ane dhayamita inosvika 508 mm. Kana uchida mapaipi asina musono ane dhayamita inodarika 1016 mm, tinogona kuagadzira tichishandisa nzira inopisa ine dhayamita inosvika 1016 mm.

API 5L inotsanangura magiredhi anotevera: Giredhi B, X42, X46, X52, X56, X60, X65, X70, uye X80.

Kune mhando dzakasiyana dzesimbi dzemapaipi esimbi eAPI 5L dzakadai seGiredhi B, X42, X46, X52, X56, X60, X65, X70, uye X80. Nekuwedzera kwegiredhi resimbi, kutonga kwakaenzana nekabhoni kunowedzera, simba remuchina rinokwira.

Uyewo, kuumbwa kwemakemikari emapombi eAPI 5L asina musono uye akasungirirwa emhando yakati hakuna kufanana, pombi yakasungirirwa ine zvinodiwa zvakanyanya uye kabhoni nesarufa zvishoma.

Kuumbwa kwemakemikari ePSL 1 pombi ine t ≤ 0.984” | |||||||

| Giredhi reSimbi | Chikamu chehuremu, % zvichibva pakupisa uye kuongororwa kwechigadzirwa a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| b yepamusoro | b yepamusoro | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | |

| Pipe Isina Musono | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Welded Pipe | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; uye Mo ≤ 0.15%, | |||||||

| b. Pakudzikiswa kwega kwega kwe0.01% pasi pehuwandu hwakatarwa hwekabhoni, kuwedzera kwe0.05% pamusoro pehuwandu hwakatarwa hweMn kunobvumirwa, kusvika pa1.65% yemagiredhi ≥ L245 kana B, asi ≤ L360 kana X52; kusvika pa1.75% yemagiredhi > L360 kana X52, asi < L485 kana X70; uye kusvika pa2.00% yemagiredhi L485 kana X70. | |||||||

| c. Kunze kwekunge zvabvumiranwa neimwe nzira Cherechedza + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Kunze kwekunge zvabvumiranwa neimwe nzira., | |||||||

| f. Kunze kwekunge zvabvumiranwa neimwe nzira, NB + V = Ti ≤ 0.15%, | |||||||

| g. Hapana kuwedzera B nemaune kunobvumidzwa uye B yasara ≤ 0.001% | |||||||

| Kuumbwa kwemakemikari epombi yePSL 2 ine t ≤ 0.984” | |||||||||||||||||||||

| Giredhi reSimbi | Chikamu chehuremu, % zvichibva pakuongorora kupisa uye zvigadzirwa | Kabhoni Yakaenzana | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Zvimwe | CE IIW | CE Pcm | |||||||||||

| b yepamusoro | zvakanyanya | b yepamusoro | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | ||||||||||||

| Pipe isina musono uye yakasungirirwa | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Sezvakabvumiranwa | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | ini,j | Sezvakabvumiranwa | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Sezvakabvumiranwa | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Sezvakabvumiranwa | |||||||||||

| Welded Pipe | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | ini,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ini,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ini,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, miganhu yeCE inofanira kunge yakabvumiranwa. Miganhu yeCEIIW inoshandiswa fi C > 0.12% uye miganhu yeCEPcm inoshanda kana C ≤ 0.12%, | |||||||||||||||||||||

| b. Pakudzikiswa kwega kwega kwe0.01% pasi pehuwandu hwakatarwa hweC, kuwedzera kwe0.05% pamusoro pehuwandu hwakatarwa hweMn kunobvumirwa, kusvika pa1.65% yemagiredhi ≥ L245 kana B, asi ≤ L360 kana X52; kusvika pa1.75% yemagiredhi > L360 kana X52, asi < L485 kana X70; kusvika pa2.00% yemagiredhi ≥ L485 kana X70, asi ≤ L555 kana X80; uye kusvika pa2.20% yemagiredhi > L555 kana X80. | |||||||||||||||||||||

| c. Kunze kwekunge zvabvumiranwa neimwe nzira Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Kunze kwekunge kwakabvumirana neimwe nzira, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% uye Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Kunze kwekunge zvabvumiranwa neimwe nzira, | |||||||||||||||||||||

| g. Kunze kwekunge zvabvumiranwa neimwe nzira, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Kunze kwekunge zvabvumiranwa neimwe nzira, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% uye MO ≤ 0.50%, | |||||||||||||||||||||

| i. Kunze kwekunge zvabvumiranwa neimwe nzira, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% uye MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Kunze kwekunge zvabvumiranwa neimwe nzira, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% uye MO ≤ 0.80%, | |||||||||||||||||||||

| l. Kune ese magiredhi ePSL 2 epombi kunze kwemagiredhi ane zvakanyorwa pasi pe j, zvinotevera zvinoshanda. Kunze kwekunge zvabvumiranwa neimwe nzira hapana kuwedzera B nemaune kunobvumidzwa uye B yasara ≤ 0.001%. | |||||||||||||||||||||

| PSL | Mamiriro Ekutumira | Giredhi repombi |

| PSL1 | Sezvakakungurutswa, zvakajairika, zvakajairika zvakaumbwa | A |

| Yakamonerwa, yakamonerwa, yakamonerwa, yakamonerwa, yakamonerwa, yakamonerwa, yakamonerwa, yakamonerwa uye yakanyoroveswa kana kana zvichibvumiranwa neQ&T SMLS chete | B | |

| Yakakungurutswa, yakakungurutswa, yakakungurutswa nethermomechanical, yakakungurutswa nethermomechanical, yakakungurutswa, yakakungurutswa, yakakungurutswa uye yakanyoroveswa | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | Sezvakakungurutswa | BR, X42R |

| Kugadzirisa kwakatenderedzwa, kugadziridzwa kwakaumbwa, kugadziridzwa kana kugadziriswa uye kuderedzwa | BN, X42N, X46N, X52N, X56N, X60N | |

| Yakadzimwa uye yakapfava | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Thermomechanical yakamonerwa kana kuti thermomechanical yakagadzirwa | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Thermomechanical yakamonerwa | X90M, X100M, X120M | |

| Zvakakwana (R, N, Q kana M) zvePSL2 grades, ndezve steel grade |

PSL1 nePSL2 zvakasiyana pakuedza pamwe chete nemakemikari neunyanzvi hwazvo.

PSL2 yakasimba kupfuura PSL1 mukugadzirwa kwemakemikari, hunhu hwekudhonza, bvunzo yekukanganisa, bvunzo dzisingaparadze nezvimwewo.

Kuedzwa kweMhedzisiro

PSL2 chete ndiyo inoda kuyedzwa kwemhedzisiro: kunze kweX80.

NDT: Kuyedzwa Kusingaparadze. PSL1 haidi kuyedzwa kusingaparadze kana paine mutengo wakaderera. Kuyedzwa kusingaparadze kunoshanda. PSL2 inoda.

(Kuedza Kusingaparadze: Kuedza Kusingaparadze uye kuyedza mu API 5L standard kunoshandisa radiographic, ultrasonic, kana dzimwe nzira (pasina kuparadza zvinhu) kuona zvikanganiso uye kusakwana mumapaipi.)

Kurongedza kurikazhinji vasina kupfeka, simbi inosunga waya, zvikurusimba.

Kana uine zvinodiwa zvakakosha, unogona kushandisakurongedza kunodzivirira ngura, uye yakanaka kwazvo.

Kungwarira pakurongedza nekutakura mapaipi esimbi yekabhoni

1.API 5L Steel Pipeinofanira kudzivirirwa kubva mukukuvadzwa kunokonzerwa nekubonderana, kubuda uye kuchekwa panguva yekufambisa, kuchengetedza uye kushandisa.

2. Paunenge uchibata mapaipi esimbi yekabhoni Unofanira kungwarira kuputika, moto, chepfu nedzimwe tsaona, uye kutevedzera maitiro ekuchengetedza.

3. Panguva yekushandisa,kabhoni simbi API 5L Pipeinofanira kudzivirira kusangana nekupisa kwakanyanya, zvinhu zvinoparadza, nezvimwewo. Kana ikashandiswa munzvimbo idzi, mapaipi esimbi yekabhoni akagadzirwa nezvinhu zvakakosha zvakaita sekudzivirira kupisa kwakanyanya uye kudzivirira ngura anofanira kusarudzwa.

4. Sarudzo yepombi yesimbi yekabhoni inofanira kunge iri yezvinhu zvakakodzera uye zvinodiwa zvichienderana nezvinhu zvakawanda zvinosanganisira nzvimbo yekushandisa, hunhu hwepakati, kumanikidzwa, tembiricha nezvimwewo.

5. Kuongorora nekuyedza zvinodiwa kunofanira kuitwa pombi yesimbi yekabhoni isati yashandiswa kuratidza kuti mhando yayo iri padanho repamusoro.

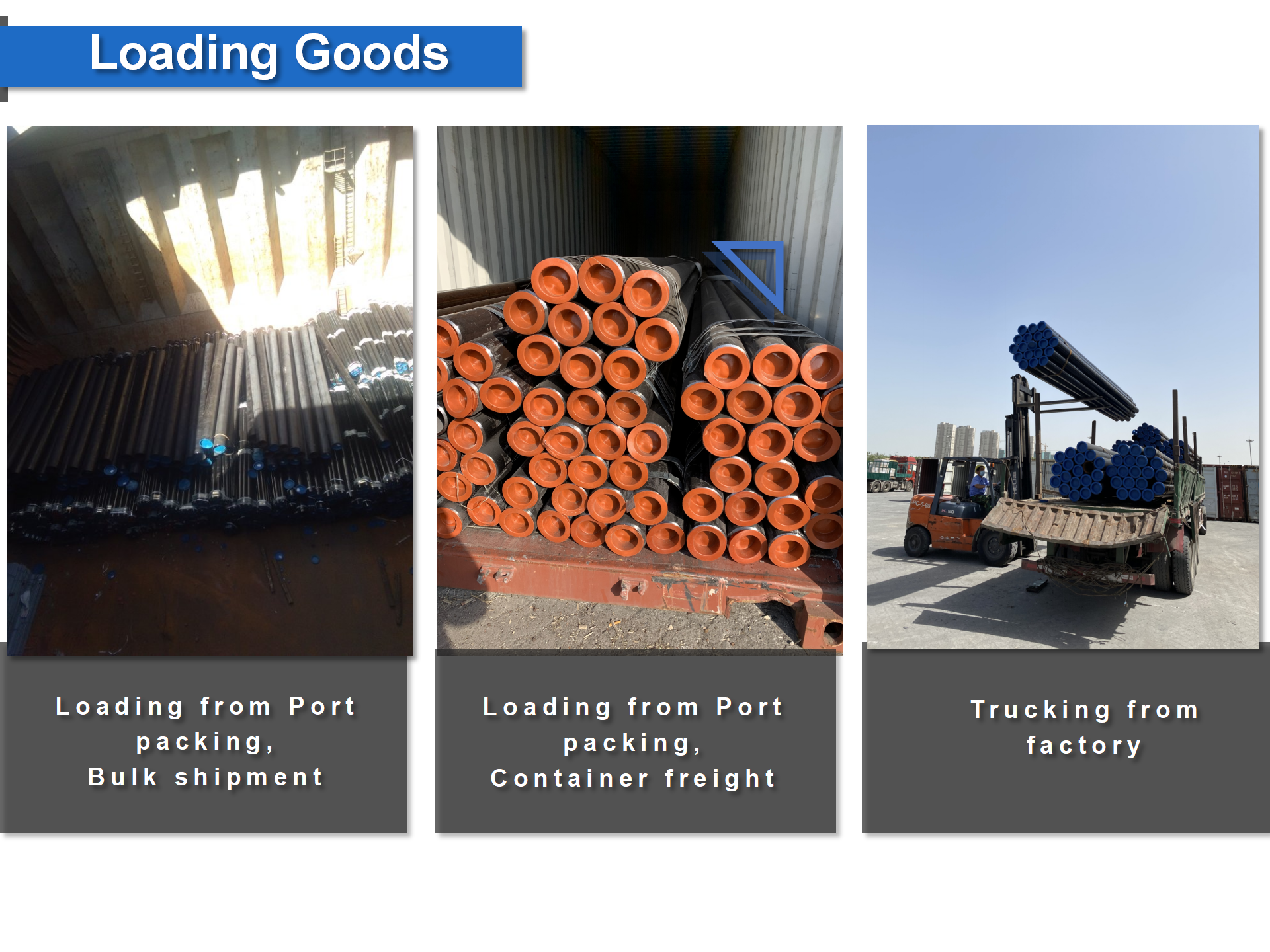

Kutakura:Express (Kutumira Muenzaniso), Ndege, Njanji, Nyika, Kutumirwa muGungwa (FCL kana LCL kana Bulk)

Mubvunzo: Vagadziri veUA here?

A: Ehe, isu tiri vagadziri vemachubhu esimbi anotenderera ari mumusha weDaqiuzhuang, muguta reTianjin, China.

Mubvunzo: Ndingawana odha yekuedza matani akati wandei chete here?

A: Ehe. Tinogona kutumira zvinhu zvako neLCL service. (Mutoro wemidziyo mishoma)

Q: Kana sampuro isina muripo?

A: Hapana sampuro, asi mutengi ndiye anobhadhara mari yekutakura zvinhu.

Mubvunzo: Uri mutengesi wegoridhe here uye unoita vimbiso yekutengesa?

A: Isu tine makore gumi nematatu tichitengesa goridhe uye tinogamuchira vimbiso yekutengeserana.